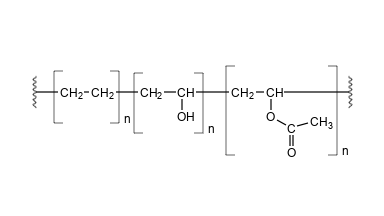

Ethylene-Vinyl Alcohol Copolymer (EVOH)

EVOH is known as one of the three major barrier materials. However, EVOH has barrier properties tens of times higher than PA and PVDC. It is a polymer material that combines the excellent processing properties of polyethylene with the high gas barrier properties of ethylene-vinyl alcohol copolymer.

EVOH is a thermoplastic high-barrier resin developed independently by our factory using proprietary technology.

This product series combines the excellent barrier properties of polyvinyl alcohol resins with the heat resistance and melt-processing characteristics of polyolefin resins.

EVOH is widely used as a packaging material for foods, pharmaceuticals, and toxic or volatile substances, significantly extending shelf life and freshness without the need for preservatives, while also reducing the volatilization of harmful substances.

In addition, it is an ideal material for applications such as underfloor heating pipes, oil-delivery pipelines, automotive fuel tanks, and other fields.

Popular application on :